The first time we met Mayuko Kita, of Kita Sake Brewery, was in Fremont at a sake trade show. An uninspiring setting (sorry Fremont trade shows) for such an inspiring person we would meet. This sake trade show was like most others, in a sea of men, few stalls were dotted with women. These sake shows are challenging because you have to wade through a lot of stuff that doesn't interest you before you find a treasure. Kayoko and I are equal opportunity, but it's especially exciting to find a product we like that is also made by a woman.

What caught our eye initially was a bottle on Kita's table that said "1996". We were intrigued. So we asked her if it was indeed a bottle of sake that had been aged since 1996. She said yes and continued to share her stories growing up with this sake and tasting it every five years with her dad to determine if it was ready. She spoke passionately about the whole process of sake-making. Unlike most of the vendors we approached that day, she didn't sound like a sales(wo)man.

Kita is the ninth generation in her family to take on the work in the brewery. Many of her predecessors were owners and took a hands-off approach to brewing. But Kita decided (while attending business school) that the only way to keep the brewery relevant and alive was to learn to brew herself. She is now in charge of tending to the koji (a mold used for many Japanese ingredients and drinks) perhaps one of the most challenging and important tasks to sake making. They say that koji-making determines the path of the end product. If you make good koji, there's a good chance you'll make a great sake.

She described to us that at Kita Brewery, they cultivate koji for 50 hours (10 hours longer than the standard 40 hours). This creates a strong character in the resulting sake structure and kokumi (richness), and also highlights the layered sweetness of the rice.

Then as an aside, she said, "You should come make it with me some time. I'll pick you up at Maibara Station."

I feverishly wrote down "30 min by car from Maibara Station" in my notes to document this casual invitation. I wanted to make it a reality.

Fast forward almost two years later on a cold January morning in 2019, we arrived at Maibara Station, where Kita's dad and brother picked us up (Kita was making koji at the time we arrived, but joined us later that day). I was so grateful that the her father and brother welcomed us with such open arms.

We all piled into a car and Mr. Kita described the events of the next two days. It was chilly – perfect sake-making weather.

You can read more about some of the sightseeing around Maibara with the Kita Family here, but the main event was the visit to the brewery the next morning.

We arrived at the brewery around 7:45am. Rice was steaming, and kurabito (brewery workers) were running around entire stretches of the brewery bringing rice to and fro large tanks. It was clearly a busy time for the brewery and I had never felt so much in the way.

We were first taken to the gigantic steamer that had just steamed a huge amount of 60% polished rice for their ginjo sake.

Here is Mr. Kita giving Kayoko a handful of rice to try.

Each piece was evenly firm, but sweet. Since the rice is so polished each grain look like a tiny round pellet.

The steamed rice then gets shoveled out onto a trough that feed onto a conveyor belt.

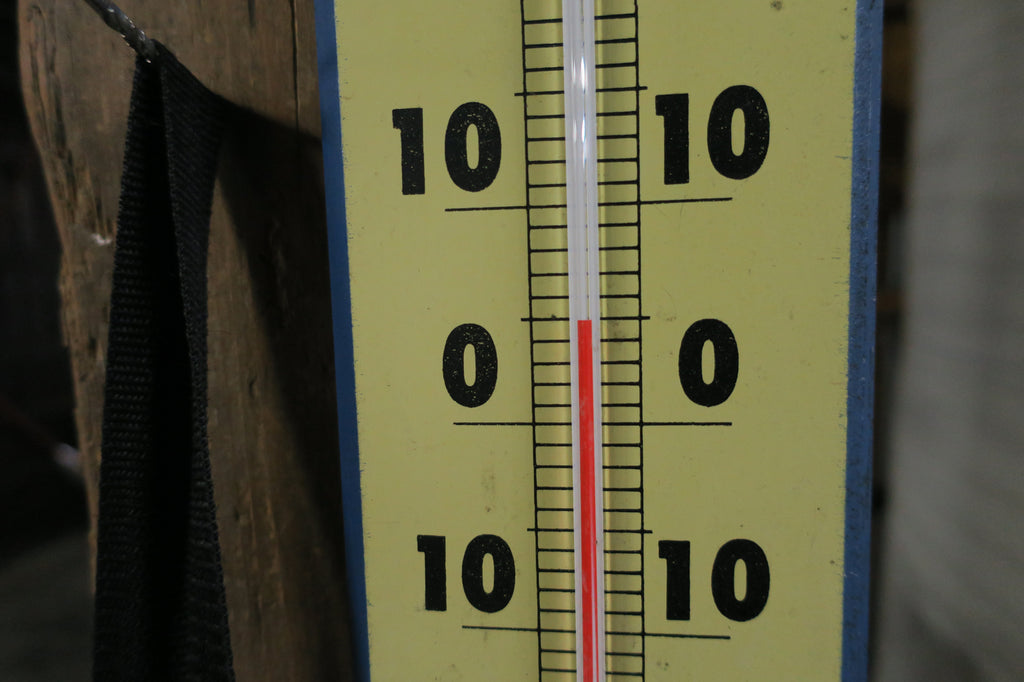

This conveyor belt cools the rice. The slower it moves, the more it cools, and the kurabito are constantly monitoring the temperature as it moves along.

The rice is then expelled into precise portions into cloth sacks.

The sacks are carefully gathered and loaded into a cart.

The cart is then wheeled off to the fermentation tank where the toji (master brewer) adds the rice to the mash.

The mash is then mixed. As more rice is added, the warmer the mash gets, and the slower the conveyor belt needs to move.

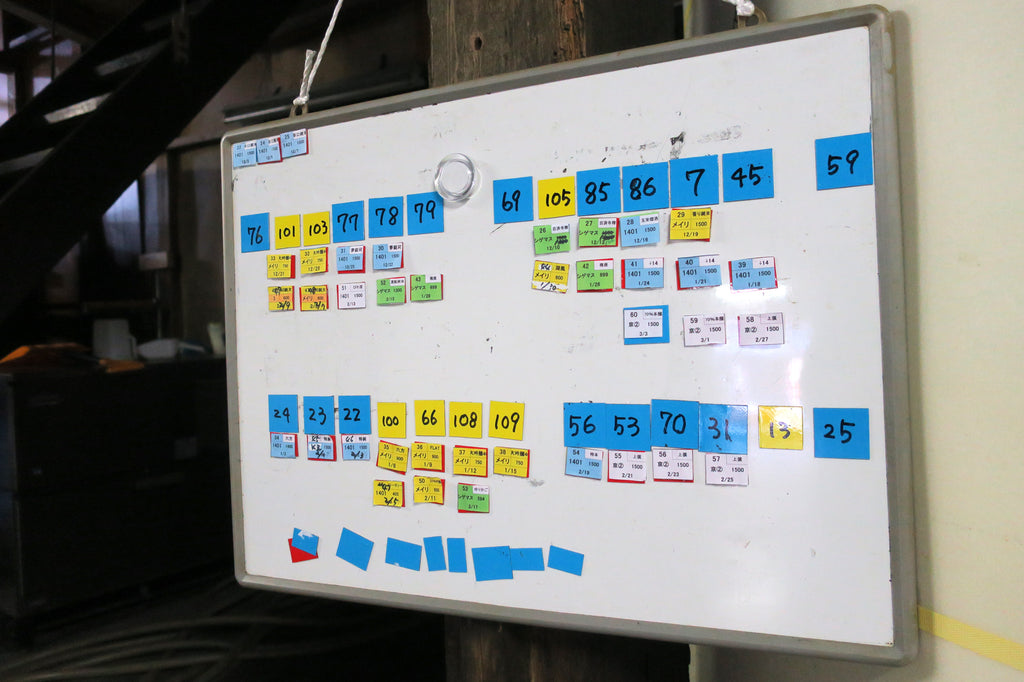

On a whiteboard, they keep track of what is in each vat, and the date it is filled.

They take out a little bit of the fermenting mash everyday and filter the sakes for testing.

Mayuko demonstrated what she does with these test sakes.

She uses this machine to determine the SMV (sake meter value, which measures the sweetness/dryness of a sake).

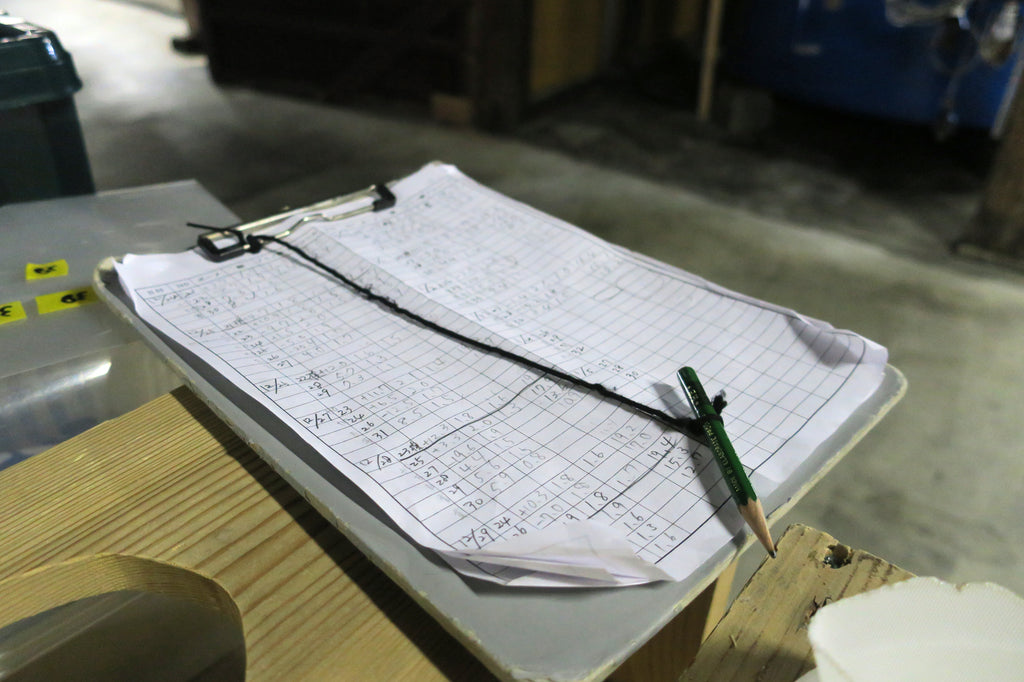

She then tests the acidity and records every change on the clipboard to monitor when the sake is ready.

Acid levels can not be reversed, so they have to stop the fermentation before it gets too high.

Mr. Kita also took us to their yeast room where they cultivate their yeasts.

They use some yeasts purchased through the guild, but also keep their original yeasts alive for many of their sakes.

Yeasts purchased from the government sake guild:

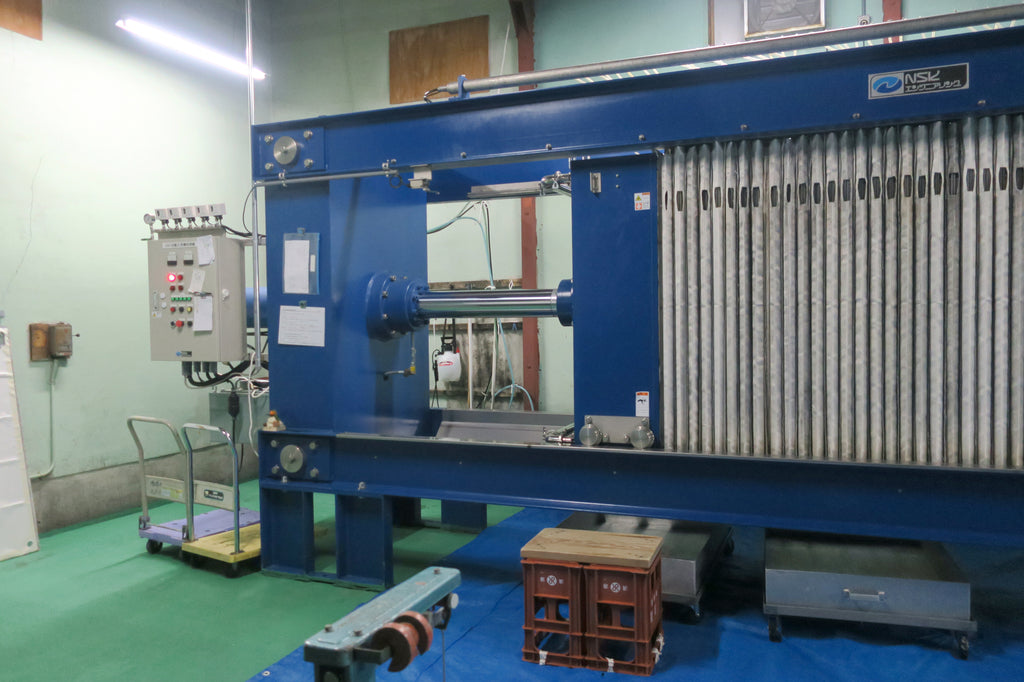

No sake-pressing was happening this day, but they showed us their Yabuta press.

Suddenly, Kita's co-worker alerted us, "it's time." And so we washed and suited up to enter the koji room.

The koji room is the heart of the brewery. It's warm, pumping, and alive. Without koji, sake has no life.

Koji mold is inside the cup, to be sprinkled onto the rice

Koji mold is inside the cup, to be sprinkled onto the rice

To prepare the koji, you start with steamed rice.

It is spread out into an even layer.

To cool down the steaming rice, we shook a large towel over the table.

Then the koji (aspergillus oryzae) is then shaken from a height of about three feet above the rice.

Watching Kita do this, it felt like a highly choreographed dance that require precise and consistent movement.

Once the koji is shaken. You wait, motionless for three minutes. Then you go into the rice. You spread it out a bit and "flip" patches of it over.

Then you repeat the process on the other side and wait another three minutes...

... and you wait for the rice to cool down to the optimal temperature.

Then the rice is then piled into a mound and boxed in.

Like a baby, the rice is wrapped up in blankets.

And like a baby, checked in on constantly by its proud parents. At the brewery, they keep an eye on their koji for 50 hours. It is like a vigil. The kurabito can not roam far during those 50 hours. In fact, Kita says she sleeps just upstairs.

Everyone at the brewery were so kind to let me into the koji room and let me work their koji – usually a highly private and secretive procedure. Before this, I had never taken part in sake-making. It was a truly eye-opening experience.

Although this was a very quick taste of sake-making, I could tell just from being there for a few hours that making sake requires intuition and physical labor but also skills in science and technology. It was interesting to see how very old techniques and tools worked alongside new advancements in technology.

After visiting the koji room, it was time to taste.

Mr. Kita poured the Karakuchi Junmai Ginjo, the most popular sake of theirs in Japan. The concept behind this sake is that they wanted to make a sake that was dry but still had koku (richness) and didn't leave a stinging dryness. In fact, this sake represents the brewery's mantra of, "making sakes that have koku and kire (clean ending)." Despite it being a junmai ginjo, it's quite light on the fruity and floral. It has a sturdy porridge-like aroma upon entry, but ends satisfyingly dry. Both Kita and her dad agree that this sake is great with raw squid, yakiniku, and simmered meats. This sake is a part of Sake Gumi this month!

The second sake he poured was their Tokubetsu Junmai, a full-bodied, smooth, earthy brew that made me fall in love with sake all over again. Unfortunately this one is not available in the U.S. I'm determined to work on that though, and bring it in!

The last sake we tried was their Junmai Nigori.

With a slight effervescence, I noticed a unique aroma – soy sauce! Despite that sounding a bit odd, I quite enjoyed that note upon entry. It gave it a dimension that I'd never experienced in nigoris, which usually just smell and taste like candy to me.

For food pairings, Mayuko-san mentioned that sakes made in Shiga tend to pair best with their local cuisine. In addition to Shiga's famous Omi beef, local cuisine also includes many fermented foods like funazushi (fresh fish pickled in salt to draw out moisture, then compressed with steamed rice to prevent oxidization and encourage fermentation), and tsukemono (vegetable pickles).

In truly humorous Mr. Kita style, the last bottle he presented was his "special blend." He poured glasses for us with a slight snicker.

It turned out it was their pride and joy, the treasure of the whole brewery – their clean, pristine, soft, and delicious well water. It was indeed very special.

I feel so fortunate to have these experiences with people all over the world who are passionate about their craft. It makes me reflect on how better I can invite people into Umami Mart. It also makes me appreciative of all the knowledge and enthusiasm people have that is overflowing so abundantly that they have to share it (without being pedantic about it).

Simply by showing and not telling, the lessons that the Kita Family taught me were many. The lesson that Kita left us with was that koji is the heart of sake making. And her father extended that lesson by proving that water is its blood.

KITA SAKE BREWERY

1129 Ikedacho, Higashiomi

Shiga Prefecture 527-0054, Japan

Comments (0)

There are no comments for this article. Be the first one to leave a message!